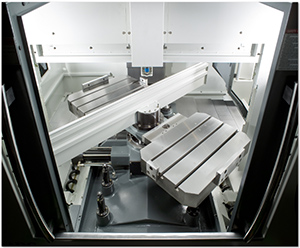

JHV-550

| Contents | Items | Units | JHV-550 |

| 3- Axes travel | X axis travel | mm | 550 |

|---|---|---|---|

| Y axis travel | mm | 400 | |

| Z axis travel | mm | 460 | |

| Distance from spindle nose to table surface |

mm | 120-580 | |

| Table | Table area | mm | 650 x 410 |

| Max. load of table | kgs | 250 | |

| T- slot | mm | 3 x 14 x 100 | |

| Spindle | Spindle taper | type | BT-40 |

| Belt type | rpm | 10000 | |

| Direct drive - opt. | rpm | 10000 / 12000 / 15000 | |

| Spindle motor | kw | 5.5 / 7.5 | |

| Spindle cooling | type | oil cooler | |

| Feed Rate | Rapid traverse (X,Y,Z) | m/min | 36 / 36 / 36 |

| Cutting feed rate | mm/min | 1-15000 | |

| X,Y,Z axis servo motor (FANUC) | kw | 1.2 / 1.2 / 3.0 | |

| X,Y,Z axis servo motor (MITSUBISHI) | kw | 1.5 / 1.5 / 2 | |

| A.T.C | Magazine type | type | Arm |

| Tool magazine capacity | pcs | 24 | |

| Max. tool diameter | mm | 75 / 150 | |

| Max. tool length | mm | 200 | |

| Max. tool weight | kgs | 7 | |

| Tool selection | type | Random | |

| Others | Power consumption | KVA | 20 |

| Floor space (L x W x H) | mm | 2400 x 2450 x 2650 | |

| Machine weight | kgs | 3400 | |

| *Design and specifications are subject to change without prior notice. | |||

Standard Accessories

- Full splash guard

- Belt type spindle 10000 rpm BT40

- Spindle motor 5.5/7.5 kw

- Arm type ATC 24 tools, BT40

- Rigid tapping

- Cooling system

- Auto lubrication system

- Spindle oil cooler unit

- Heat exchanger

- Telescopic cover for 3 axes

- Work lamp

- Three-color call light

- Tool box

- Coolant gun

- Screw tyep chip conveyor with chip cart

Optional Accessories

- Transformer

- CE mark

- Spindle motor 7.5/11 kw

- Belt type spindle 12000 rpm, BT40

- Direct drive spindle 10000/12000/15000 rpm

- Built-in type spindle 24000/30000/36000 rpm

- Rear coolant flushing device

- Disk type oil skimmer

- Coolant through spindle (with sealed splash guard)

- Chain type chip conveyor with chip cart

- Roller type linear guideway

Auto Pallet Changers

A, B Table driving by oil tank to rotate in CW / CCW directions, complete the table exchange swiftly

Coolant Flush Device for APC Shield

Coolant flush will be activated automatically before APC exchange to clean chips and enable APC for orientation and clam ping

LinkedIn

LinkedIn Instagram

Instagram